Today’s very strict competition force manufacturers to keep their productivity with minimum downtimes. At this point ARS supports customers by doing rewind of rotating machine at customers’ site through experienced winders and engineers.

Rewind at site starts first inspection to determine required windings and winding materials. After transporting these materials, ARS send its experts and equipment to carry out rewind at site. When customer leaves machine to ARS at their own workshop rewind work start sometimes with contribution of end user. Oven mostly supplied by end users and in the case of lack ARS use special tent and heaters to dry windings.

ARS experts remove old coil, clean and test core then install new coils, a dielectric strength test is applied for individual coils (2xUn+1 kV AC) After completion of connections done by silver soldering final electrical tests are executed. After preheating varnish is applied and stator/rotor dries in oven then machine is ready for assembly and run

One of the biggest advantages of rewind at site are cost and time for the customers.

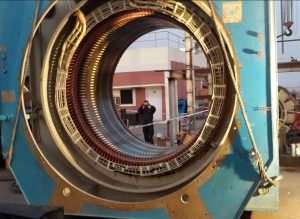

Cleaning of stator slots after removal of old coils

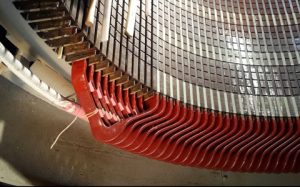

Assembly of new coils

Assembly of new coils

After coil installation before varnishing

Preparation of coil data sheet before execution of rewind at site

Stripped overhang insulation is renewed to keep machine in operation until convenient rewind time for the customer.

Manufacturing new coils

Dismantling of old coils

Cutting of overhangs

Removing of old coils

Core repair (if necessary)

After core recovery final ring flux test preparations

Thermal graphs during ring flux test

Coil geometric appropriateness checks

Slot wedge checks

Oven for drying purpose (by KEL)

Assembly of new coils

Applied coil dielectric strength test for individual coils (2UN+1kV)

Fixing of overhangs to support ring

Serial connection of coil leads

Completion of rewind and applying varnish

Ready for assembly